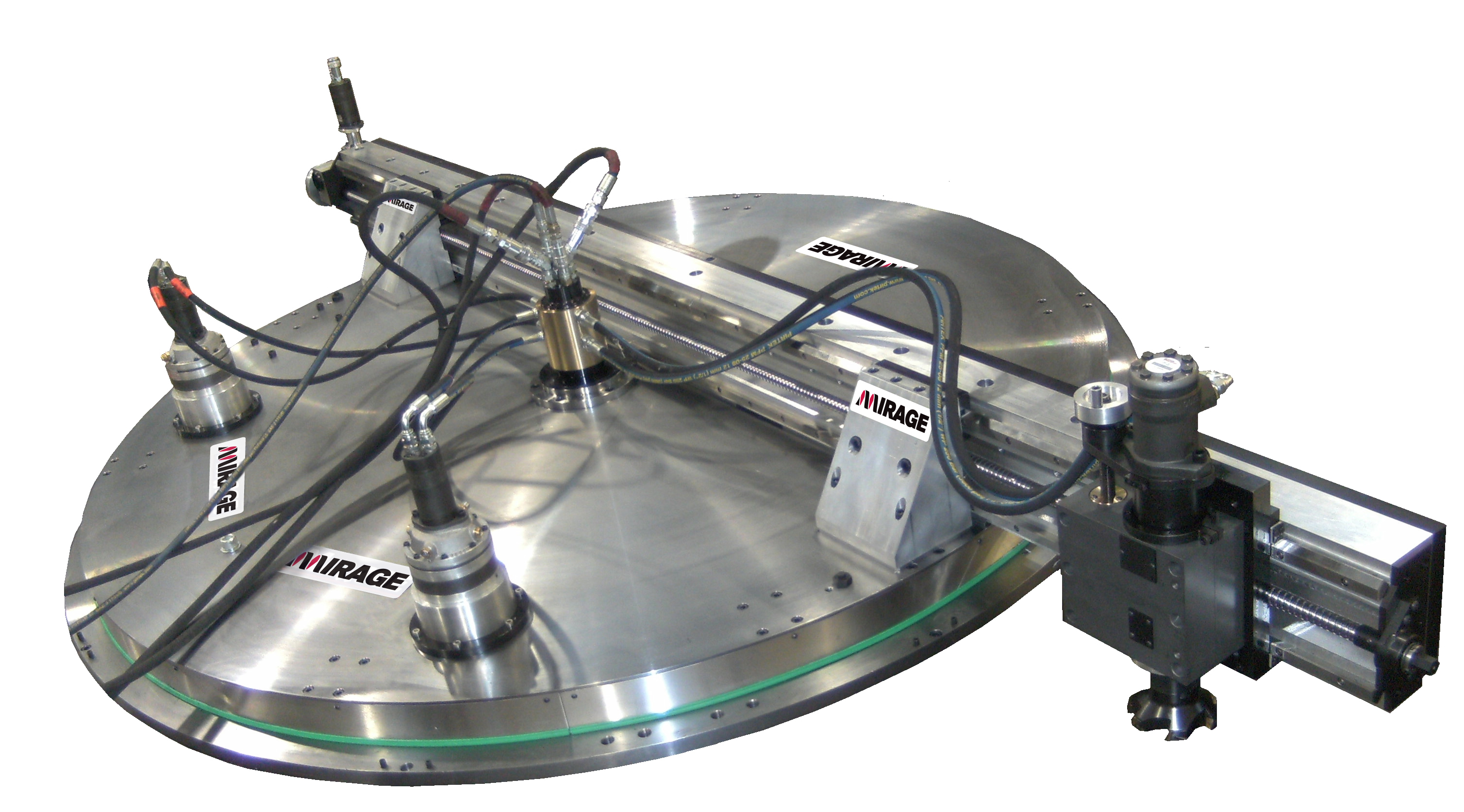

Unique flange machining concept, which ensures fast material removal with high accuracy. The hydraulic-based mounting system allows for fast and accurate positioning of the machine. Device specially designed for wind turbine tower processing.

The key features of the machine:

- Quick installation of the machine with hydraulic system

- Can be used in the production process

- Installation on the inner diameter

- Machining of flange rebates

- Precisely adjustable rotation and feed

- Machine radial-feed

Typical work in which the machine is used:

- Wind tower base machining

| Milling diameter | 2500 – 4500 mm |

| Clamping diameter | 2500 – 4000mm |

| R.P.M | 0 – 5 |

| Flatness tolerance | 0,05mm na każdy 1 m |

| Hydraulic motor | 3,75 kW |

| Air consumption needed | 6 bar, 3 m3/min |

| Hydraulic oil needed | 60l/min |

| Machine weight | 3610 kg |

| Milling head speed | 0 - 400 mm/min |